There is a new option for controlling an 8 or 16 channel relay board. You know, those really inexpensive boards for an arduino or a Pi. They typically cost between $4 and $8 everywhere. I want to use them for my lighting control boxes. Mainly due to their low cost and ease of programming.

I like lots of lights and lots of control so I need lots of relays. Getting 8 relays for $4 is too good to pass up. Also, they use listed relays (cRUus) so that might help my inspections, my biggest problem.

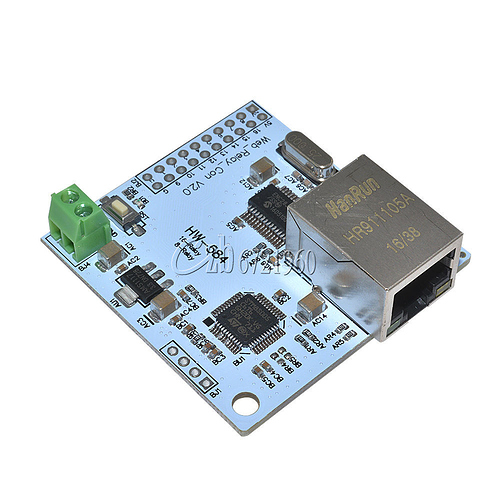

I was going to control them directly from the pins of my Orange Pi One boards using a voltage shifter, 3 to 5v, but I think I found a better solution. This little board, I found, costs only $8 each, including shipping. It plugs onto the relay board and has an RJ45 network jack on it that allows me to control the relays using a network connection. This should eliminate a lot of extra wiring, simplifying the whole lighting system. Also it will allow me the option of putting lighting control boxes anywhere I need to without having to include control logic boards. I can centrally locate all of my control in one panel and send the control codes to the individual relay panels, closer to the lighting.

You can buy the relay boards with the net card as a unit but the price I ridiculous, going up to almost $30 for the same product.

I still have a lot of work to do before this is a done deal but my boards came today so I plan on bread boarding up a box and see if I can get all of the bits and pieces to work correctly. The really great thing about these boards is, I can buy a bunch of extras and keep them on hand in case of equipment failure. This increases the plug and play aspects of the system making it easier to maintain and lowering the “oh crap, the lights just went out” factor. Something we’ve all thought about at one time or another. I would like to build in as much redundancy into the system as I can afford and at these prices, that’s easy.

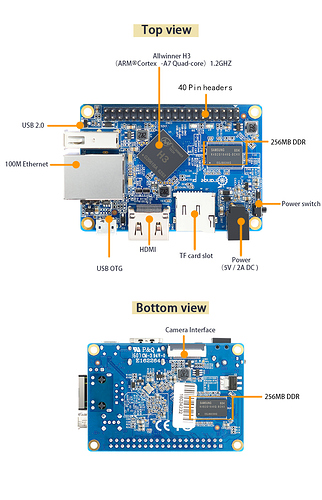

Here’s a picture of the Orange Pi that I plan to use for my button controllers. At $13 each they are a bargain. Also they are $13 each and they have built in RJ45 networking. I like having hard wired networking for all of the boards.

I am going to use a pine 64 for my main brain with Open House, node red, etc. on it. There is an image already made for it with all of the firmware already loaded and ready to go at Open House. At $35 for the pine, it’s a bargain. All of the boards I’ve chosen, besides being cheap, are well supported and readily available. The pine is guaranteed to be available by the mfg. at least until 2021. I will stock at least one extra, loaded and ready to go in case of failure.

All totaled, each 8 channel relay box should cost about $35 each including all of the power strips for the 110v input. I also just purchased a Square D 70A circuit breaker sub panel to power the lighting control panel in my attic. Code requires you to have a disconnect within sight of any remote panel so I decided that having the breakers next to the lighting panel was the best idea… Beats having to put lockout tabs on the main breaker panel on 4 breakers. Two of my lighting control boxes are in the basement equipment panel which is only a couple of feet away from the main panel so no lockouts needed.

That’s a total of 6 lighting control panels for the whole house with 8 circuits in each for a total of 48 possible controlled lights in the house. Some of the relays might control other loads, such as bathroom ventilation fans and such but if I needed more relays it would be easy to swap out the 8’s for 16 channel relay boards for only a few dollars more. One more interesting this to consider is, if I needed a wireless wifi switch, because the relays are network controlled, it would be easy to wire in one using an esp8266 board. I could also add wireless occupancy sensors in the same manor.

Now I just need to program the whole thing to talk to the relay boards. Some instructions I found on one of the sales sites at Ali Express showed this.

Open the browser, the address bar input: http://192.168.1.4/30000 enters the control interface

1, the relay controls the HTTP command:

Relay 1-8 command:

Http://ip/ port /00:Relay-01 OFF

Http://ip/ port /01:Relay-01 ON

Http://ip/ port /02:Relay-02 OFF

Http://ip/ port /03:Relay-02 ON

Http://ip/ port /04:Relay-03 OFF

etc.

Shouldn’t be too difficult to come up with a program to control the relays over tcp-ip. Worse case scenario, it looks like there is a place for a serial header on the board for uploading firmware. I think the network chip on the board is a pretty standard one and there should be some more information on the net about programming. I’ll let you know what I come up with as soon as I get the time to do the bread boarding. Right now I’m knee deep in wiring the home run lighting to the plywood panel backer board in the attic, where the lighting panels will be mounted. It’s summer here and the attic has been in the 90deg F plus temperature every day. Kind of slows me down when I’m roasting and working at the same time. Too many water breaks. This was a lot easier 20 years ago. Getting olds a bitch, as they say. If I don’t die of heat stroke or dehydration, I update this post soon, at least with more pictures.

MisterFixIt1952