As stated in my house remodel blog posts on lighting, I have thought more about lighting than almost any other other topic. The number one reason for having the lighting control in one place, rather than distributed, is power source and ease of programming. If possible, homerun lighting is the obvious choice for lighting control.

The next in line when considering lighting is power source, AC vrs DC. Lighting is the one area in HA (home automation) that is frustrating to me. AC lighting products are readily available, making it the obvious choice. One problem is, there are 2 common standards globally, 220v & 110v. This fact complicates things and is a barrier toward price reduction through economy of scale. Actually more of a pain in the butt than a barrier since both markets are rather large. I often see promising new technology available in China (220v) that is readily available at a reasonable price but not yet available in the US (110v) market. Bummer!

Back in my infancy days of HA I used X-10 modules in my initials stabs at lighting control. This was when I was attempting to adapt traditional wiring. At less than $10 per module, this was an affordable option for my budget. Since X-10 is one way communication, meaning the controlled device does not acknowledge receiving the command, X-10 was sometimes hit or miss. Newer evolutions of X-10, invented in europe, were more reliable, cheap and 220v. After waiting and waiting for these new modules to be made available in 110v with no success, I finally gave up on X-10 all together. The US market for X-10 had almost collapsed, being replaced by other new technologies such as zwave. Unfortunately these new devices are still in the expensive category, the cheapest basic switches start at about $25-30. BTW, if anyone wants some new X-10 products cheap, I have tons in unopened boxes.

AC lighting control, in a standard wiring configuration, is inordinately expensive in that you need to replace existing switches with expensive replacements, which can cost $35-75 (or more) apiece. When you consider how many switches there are in a house, the price becomes astronomical very quickly. Not to mention the replacement/maintenance costs over time. Anyone who has used dimmers knows what a short life they tend to have. When you factor in the additional cost of proprietary controller devices, for remote control by radio or the web, the costs further skyrocket. Using home run wiring and centralized controls eliminates the need for expensive switches (distributed control). A $2 LED button is a much better and cost effective idea.

Now, getting back on topic, AC vrs DC wiring, sorry for the topic wandering, it’s easy to do when discussing HA. With AC wiring there are two choices, The expensive one, distributed control (smart switches) or, if you can do the major rewiring required, home run wiring. If you use AC home run wiring, you get to use off the shelf lighting fixtures, readily available at any big box home improvement center. The problem with that is you are dealing with mains level voltages, either 110v or 220v. In the new world of LED lighting, this is somewhat of a conundrum. LEDs run on much lower DC voltages and DC control of 12-24v circuits is much easier to accomplish with low cost circuitry and devices. In fact, the greater part of an AC lighting control system is devoted to using DC circuits to control AC voltages, sending that to the light fixture where it is then converted to DC voltage to power the LED lighting. Anyone who has ever used LED lighting know that those 20 year LED light bulbs always fail because although the LEDs might last 20 years, the power supplies that convert the AC into 12v DC always fail first. Although you can buy DC lighting, mostly from chinese sources, these are not generally UL approved and thereby not suitable for installation according to current electrical codes. Plus, since these are not off the shelf devices, you would need to keep a stock of replacements in case of failure, that is, unless you would like to wait 3 weeks in the dark for replacements to arrive from China.

The exception to this AC, DC dilema is LED strip lighting. This falls into a somewhat gray area. Running on a 12-24v DC power source, these devices are considered low voltage devices and thus are covered under the more liberal low voltage electrical codes. This makes their installation and acceptance by the local inspector more of a hit or miss affair. I personally plan on using a combination of RGB strip lighting located behind my ceiling crown moulding and AC LED recessed can lights in most of my main rooms with a central hanging light, possibly with a ceiling fan, for decorative purposes. My old house has 9 ft. ceilings so this lighting/decorating scheme works quite well providing accent lighting, main lighting and air circulation. I happen to live in a part of the US that only requires air conditioning, maybe, 4 weeks out of the year so ceiling fans are a more practical solution and add a quaint ambiance to the decor. The RGB strip lighting gives me great mood control and the cans provide controlled area lighting. With so many lighting sources to control, in each room, using anything other than home run wiring and control would be inordinately complicated, not to mention expensive. Especially given my penchant for multiple light switches. Most of my rooms have more than one entrance so having a switch at every doorway becomes complicated using conventional wiring, requiring 3 and even 4 way switches. Using home run wiring also allow me to add dimming, remote control, scene lighting and occupancy sensing to any of the circuits at any time, something I am particularly happy with as this allows me to get things up and running then add the goodies later, as I have time. I even have plans to add several, strategically placed, wall hung, touch panels made from inexpensive 9 or 10" android tablets. These can be purchased for less than $100 each and because they need only run a web page, I can use older slower surplus or used tablets for real cheap.

As an option for the average Joe (or Joanne) who wants to redo his (or her) house for HA, using cat5 switch wiring and home run lighting might not be as daunting a project as you might think. As a veteran home remodeler, it is my experience that most homes could be rewired in a home run configuration if you didn’t need to use conventional switch circuits. The hard part of wiring any room is getting the wires from the ceiling to the walls through the top or bottom plates and making the whole thing work when your done. Also the new codes require power at the switch, a requirements that further complicates a difficult situation. With home run lighting you just need to run wiring in an attic to a central location, or locations. All of your lighting power comes from that central point and since LED lighting is so energy efficient, the circuit requirements are minimal. In fact, you could run all of a house’s lights off of one 20A circuit, although that is not a good idea, for obvious reasons. All of my lighting circuits are 15A using 14(2) wire.

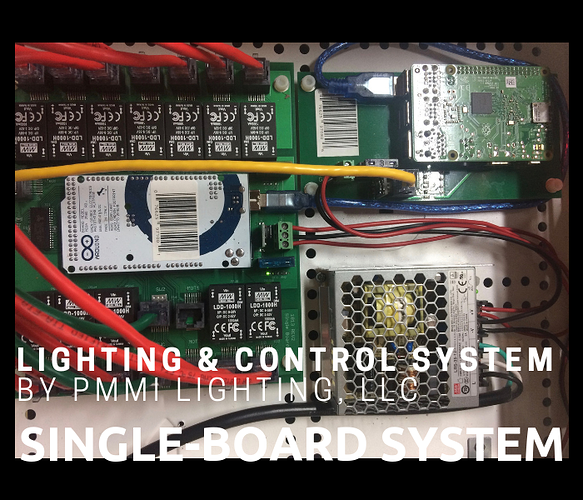

Using cat 5 wire for the switches also makes the job significantly easier then romex romex. One cat 5 cable will control as many as 4 maybe 6 lights. Running network wire through walls is also much easier than romex, you are not even required to use a junction box, only a drywall mount for the plate cover. Also, 1000 feet of cable costs as little as $60. If you were in a situation where you couldn’t run a cable, you could always always resort to using one of the wifi solutions to signal the controller, such as an 8266 module. A bit more complicated, but doable. It might even be possible to use the existing switch wiring (be sure to mark it as low voltage). Also, you are not limited to having one home run panel. Because a panel essentially consists of a CPU (arduino or pi) and a relay board and power supply, you could have as many as required distributed throughout the house and connected over tcpip or WiFi. This makes a retrofit a less daunting possability. If you have an unfinished attic or basement, you could do the job yourself with just a few simple tools. More importantly, you could do the job a little at a time without disturbing your existing wiring, bringing each circuit on line as it was done. This will definitely make the wife happy (always a good idea) and make the idea easier to sell. Also the cost could be as little as $500 since no expensive equipment or proprietary switches are required.

One more important point to take into consideration, inspection wise (if your doing the inspection thing). All new electrical codes require arc fault breakers in all bedrooms, at a minimum. Some jurisdictions even require them in dining rooms. Eventually they might be required in every room and at $40 per breaker, that gets expensive very fast. By using home run wiring, there are no high voltage switches in any rooms, therefore there is no need for AFCI circuits for the lighting. No switch, no arc! Since I always separate my lighting from my outlet circuits, that would normally require 2 AFCI breakers for each bedroom or at a minimum 2 for every 2 bedrooms. The savings add up fast, plus AFCI breakers are notorious for failing frequently. Especially if they trip several times. Worst idea ever brought to us by the powers that be, in my opinion, and I am generally a safety conscious individual. A reasonably well wired house should not burn down due to arching. I think this is taking safety to an extreme but that is just my opinion (end of rant).

Anyway, getting back to the subject, if DC lighting were more available, that would, in my opinion, be the way to go. Unfortunately at this time I don’t see it as a viable option. I think we are stuck with AC lighting for the foreseeable future or at least until HA is more of a mainstream happening, not just the dream of a few enlightened individuals, such as ourselves.